"Just wear your damn mask..." (jimal)

"Just wear your damn mask..." (jimal)

09/18/2016 at 13:44 ē Filed to: None

3

3

2

2

"Just wear your damn mask..." (jimal)

"Just wear your damn mask..." (jimal)

09/18/2016 at 13:44 ē Filed to: None |  3 3

|  2 2 |

Finding a simple solution to a problem that has been driving you crazy forever.

Ever since I got my truck running, Iíve been chasing this intermittent shake/noise in the engine/transmission at idle. At first I thought the issue was caused by the P.O. using a 350 flywheel (internally balanced) on the 400 small block (externally balanced) he installed, so I replaced the flywheel and clutch assembly, adjusted everything and the shudder/noise sort of went away, but then came back in time. Since I donít drive the truck all that often, I sort of dealt with it. Until today.

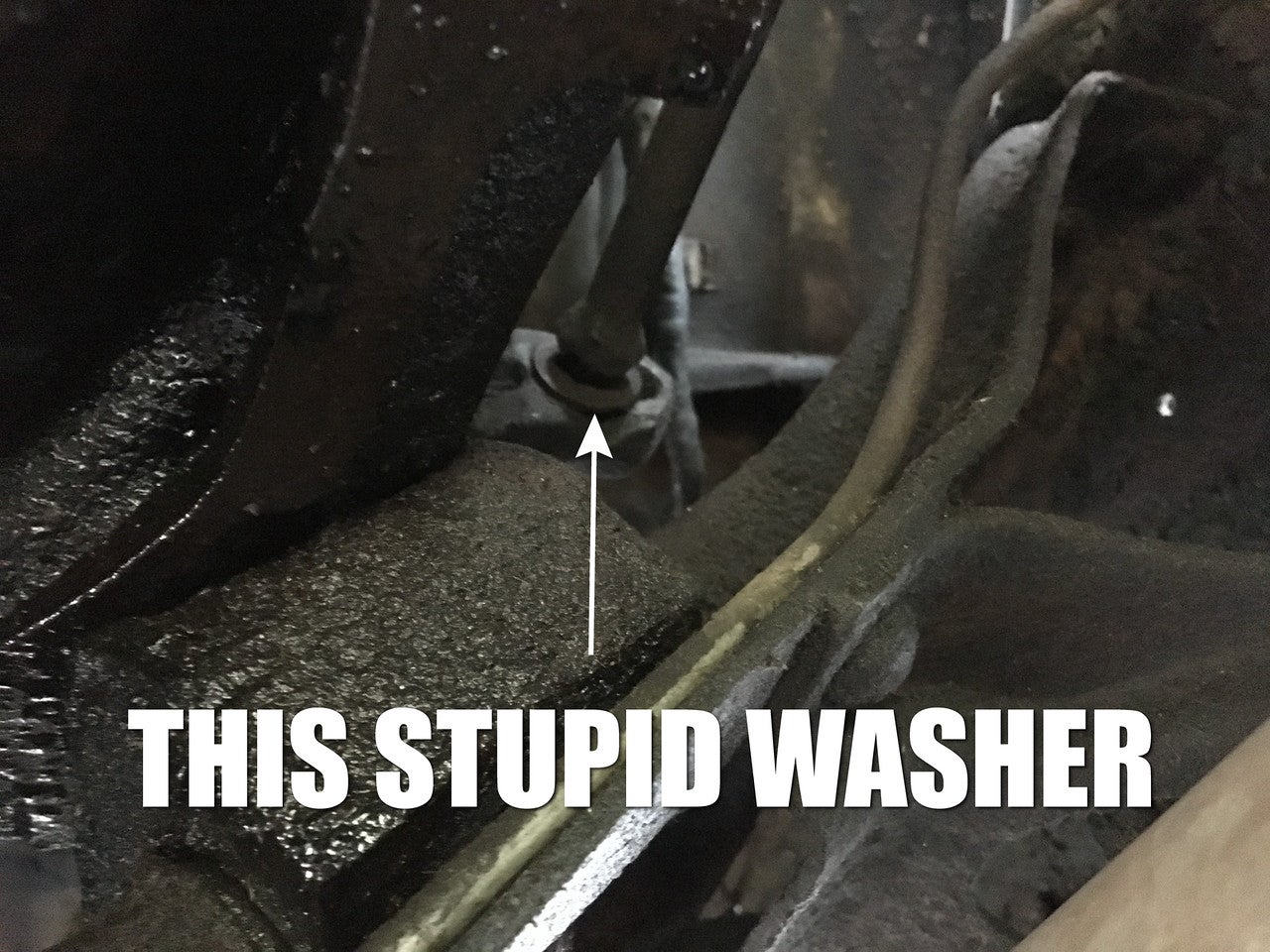

Thinking that I either screwed something up, like not installing the pilot bushing in the crank, or that the throw out bearing in the clutch kit I picked up from NAPA a couple years back, I started poking around underneath. After consulting the shop manual, I started by loosening up the adjustment on the rod that connects the clutch fork to the rest of the clutch linkage. Started the truck, and the shake and noise are both gone. So I went through the process of readjusting the clutch, and noticed that every time I tried to turn either of the lock nuts on the push rod, the rod moved around. Thatís when I noted the washer.

The rod is supposed to be held in place in that v-notch by (what they describe as) a nut. At some point in the past that nut must have been lost, so someone stuck a washer in there, so the rod would move around, and the free play would never be the same twice.

After digging through the coffee cans of nuts and stuff that came with the truck, I donít have the missing nut, so I had to order one. Still, that is a lot better than having to pull the transmission back out to discover the damage that a bad throwout bearing or pilot bushing would have cause. Win.

Deal Killer - Powered by Focus

> Just wear your damn mask...

Deal Killer - Powered by Focus

> Just wear your damn mask...

09/18/2016 at 14:03 |

|

The two best fixes Iíve had on my Focus corrected a horrible squeak every time I hit a bump. The squeak was caused by the emergency brake cable, which is held up against the mid-point of the body by a small metal loop which the cable passes through on its way to the rear drums. Over time, the plastic coating over the cable wore away, and the metal cable would rub against the loop, causing the squeak every time the car would hit a bump. It was maddening, as I couldnít pin done the source for months after I bought the car. I knew it was caused by the rear suspension, and after many hours of pushing this and pulling that, finally came to the E-brake cable. I cleaned the dirt away from the metal loop, and noticed the wear to the plastic. A simple plastic shim and some zip ties and the squeak was banished!

V8Demon - Prefers Autos for drag racing. Fite me!

> Just wear your damn mask...

V8Demon - Prefers Autos for drag racing. Fite me!

> Just wear your damn mask...

09/19/2016 at 02:33 |

|

Two years. For two years I was chasing a vacuum leak on a car that I didnít daily drive. Figure I drive it 2 maybe 3 times a month. In cold weather, it would give me a hissy fit on HOT starts. Cold startup was fine. I checked and rechecked everything I could think of. Vacuum gauges showed NOTHING out of the ordinary. Then one day I decided on a bigger throttle body (the car is heavily modified). Swapped it out. Problem solved. The shaft seals on the shaft of the throttle body were allowing juuuuust enough air through at idle to cause the car to be a crank. Havenít had any issue since the swap....